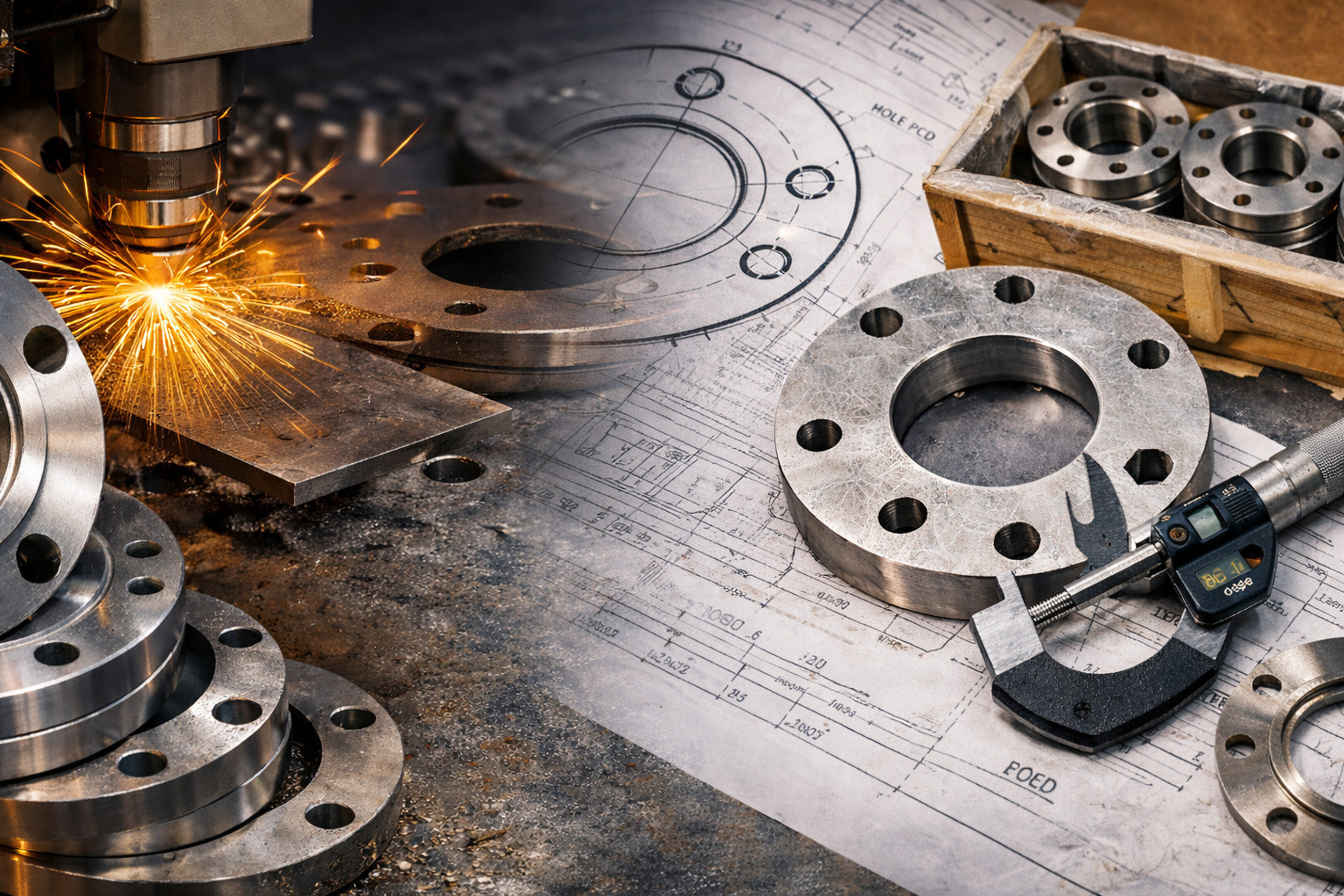

Inside Our Sheet Metal Manufacturing Facility: Machinery, Capabilities & Processes

Eterna Global Solutions LLP designs and manufactures premium sheet-metal enclosures, server and networking racks, and industrial cabinets. For global sourcing teams, reliable outcomes come from suppliers who control the process end-to-end. Below is a transparent overview of our in-house machinery—organized by process stage—so you can evaluate capability depth, capacity, and control.

Why machinery transparency matters

Many suppliers outsource key steps such as CNC cutting, forming, welding, or coating. While outsourcing can work for some projects, it often increases variability and makes lead times harder to predict—especially across repeat export orders.

With in-house capability, you get stronger process control and repeatability across batches.

- Better control over dimensional accuracy and fitment

- Predictable lead times and faster engineering changes

- Consistent surface preparation and coating outcomes

- Scalable assembly with repeatable tooling

Manufacturing capabilities & machinery

Click a process category to view the detailed machinery list (models, working ranges, and quantities).

How these capabilities support export-ready production

This machinery setup supports controlled manufacturing for export programs where consistency, packaging discipline, and repeatability matter. It also reduces dependency on external subcontractors—helping keep schedules predictable.

- Dimensional consistency: CNC blanking and press brakes support repeatable fitment across batches.

- Surface quality control: finishing and batch powder coating improve uniformity and reduce cosmetic variation.

- Scalable assembly: dedicated pneumatic tooling supports higher-volume build without compromising consistency.

- Planning and traceability: ERP alignment supports scheduling, execution control, and documentation readiness.

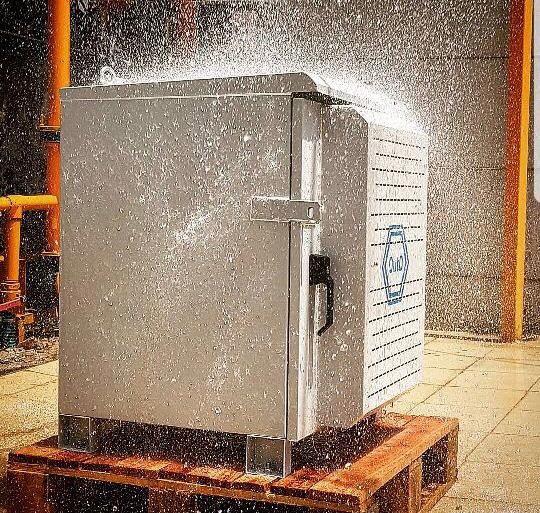

Typical products manufactured using this setup

Our in-house processes are commonly applied to production of:

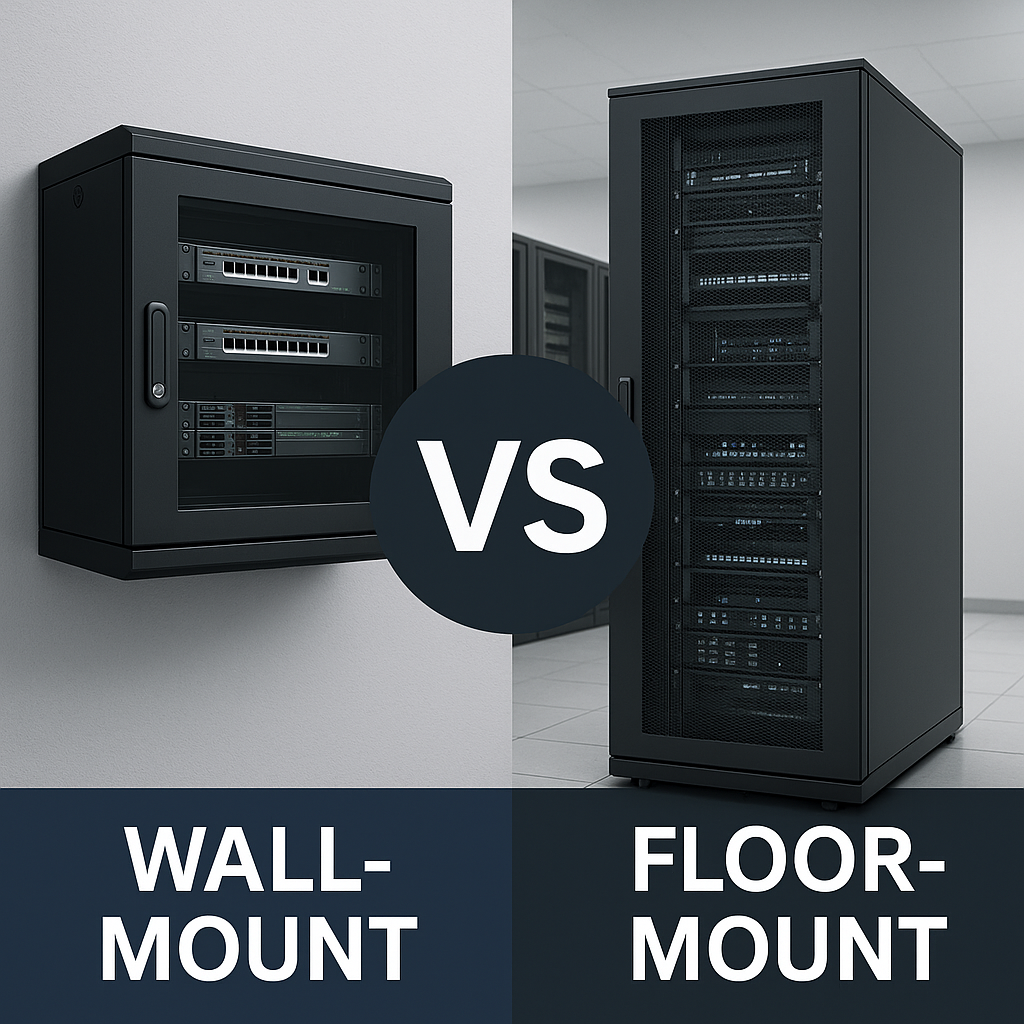

- Server racks (wall-mount & floor-mount)

- Network and telecom cabinets

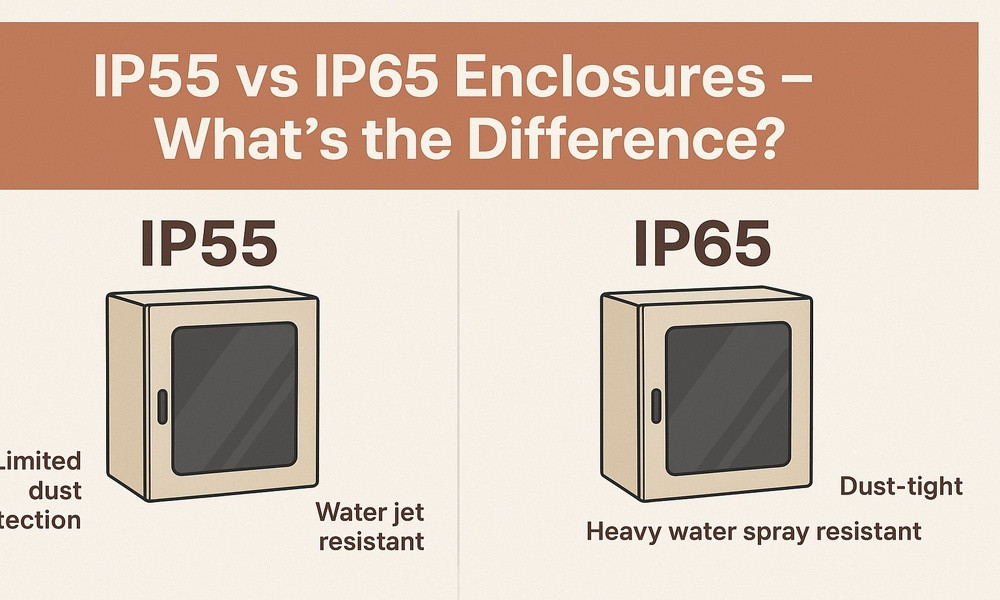

- IP-rated outdoor enclosures

- Electrical panels and industrial cabinets

- Custom sheet metal assemblies and sub-assemblies

-20082508144130.jpg)

-20082508385589.jpg)

-29112509574730.jpg)

-18122502213226.png)