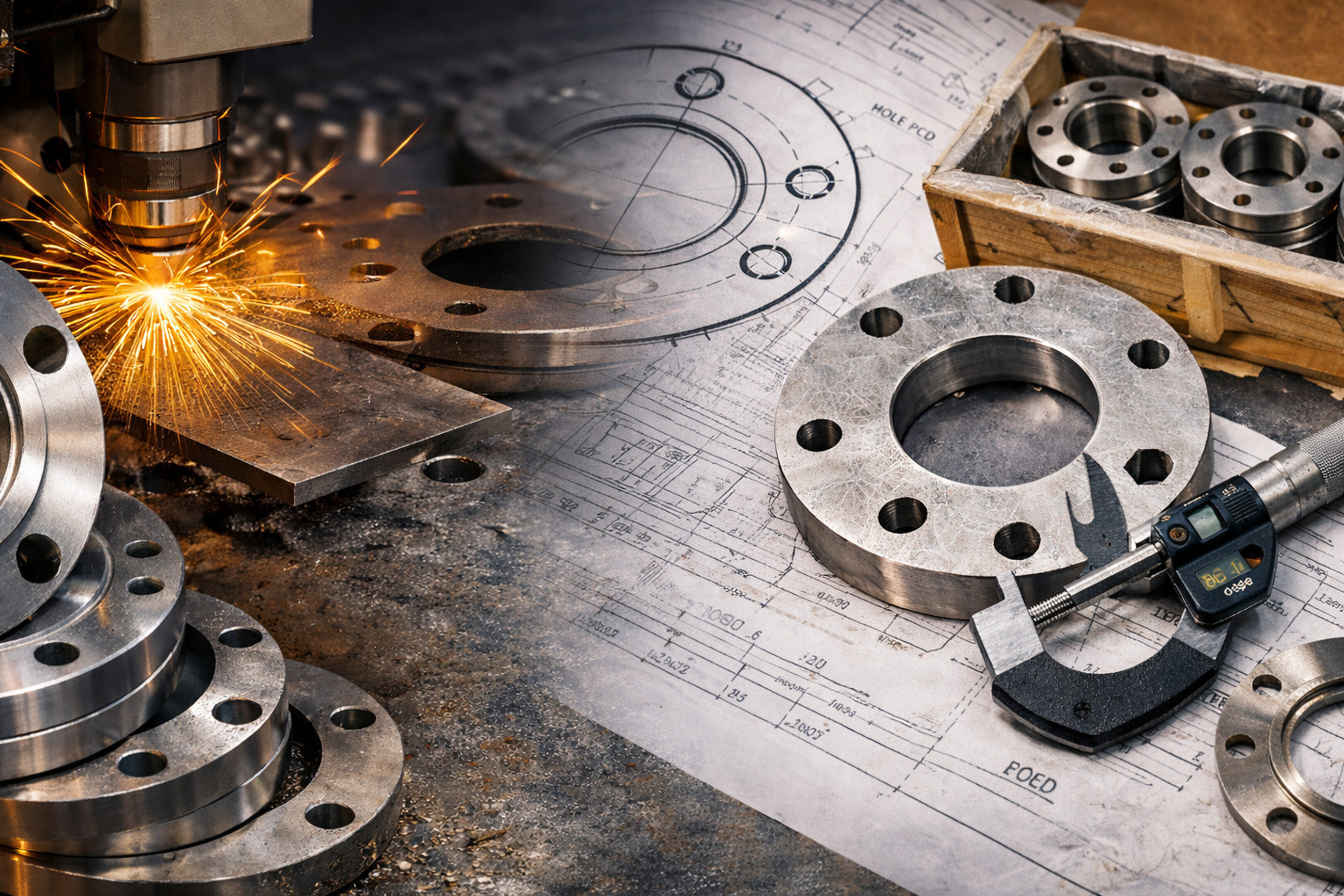

Why teams source sheet metal from India

India has become a mature manufacturing base for precision sheet metal—especially for enclosures, welded assemblies, brackets, frames, and kitted products. The best outcomes come from selecting suppliers with process maturity and clear documentation, not just low unit pricing.

Process capability

Laser cutting, punching, bending, welding, hardware insertion, and powder coating are widely available in export-focused facilities.

Repeatability & control

Stable outputs depend on controlled routing, in-process checks, and clear acceptance criteria—especially for welded and coated assemblies.

Documentation discipline

Revision control, inspection reporting, and traceability reduce rework and surprises at receiving.

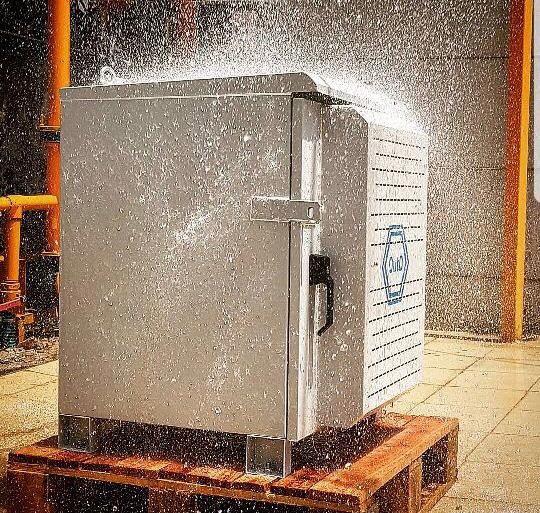

Export packaging readiness

Defined packaging SOPs help prevent transit damage and standardize kitting/labeling across SKUs.

What “export-ready” should include

A dependable export partner operates with a system—not ad-hoc production. During vendor selection, look for evidence of the following:

- FAI / First Article readiness: measurable inspection outputs tied to drawings and revisions

- Controlled change management: drawing/BOM revision tracking and documented deviations

- Finish consistency: coating specs, surface preparation discipline, DFT targets when required

- Kitting & labeling: hardware kits, manuals/QSGs, SKU-level labeling, packing lists

- Packaging SOP: corner protection, abrasion prevention, palletization rules, drop/stack logic

Risk reduction: a sourcing workflow that works

The fastest way to reduce supplier risk is to run a gated approach that forces alignment early—before scale.

- Step 1 — RFQ alignment: confirm assumptions (materials, tolerances, finish, packaging, included hardware)

- Step 2 — Prototype build: validate fit, finish, assembly sequence, and packaging performance

- Step 3 — Acceptance criteria: lock measurable requirements (critical dimensions, cosmetic zones, coating specs)

- Step 4 — Controlled ramp: increased quantity with inspection checkpoints and packaging verification

- Step 5 — Steady-state supply: routine QC reporting and continuous improvement loops

-20082508144130.jpg)

-20082508385589.jpg)

-29112509574730.jpg)

-18122502213226.png)