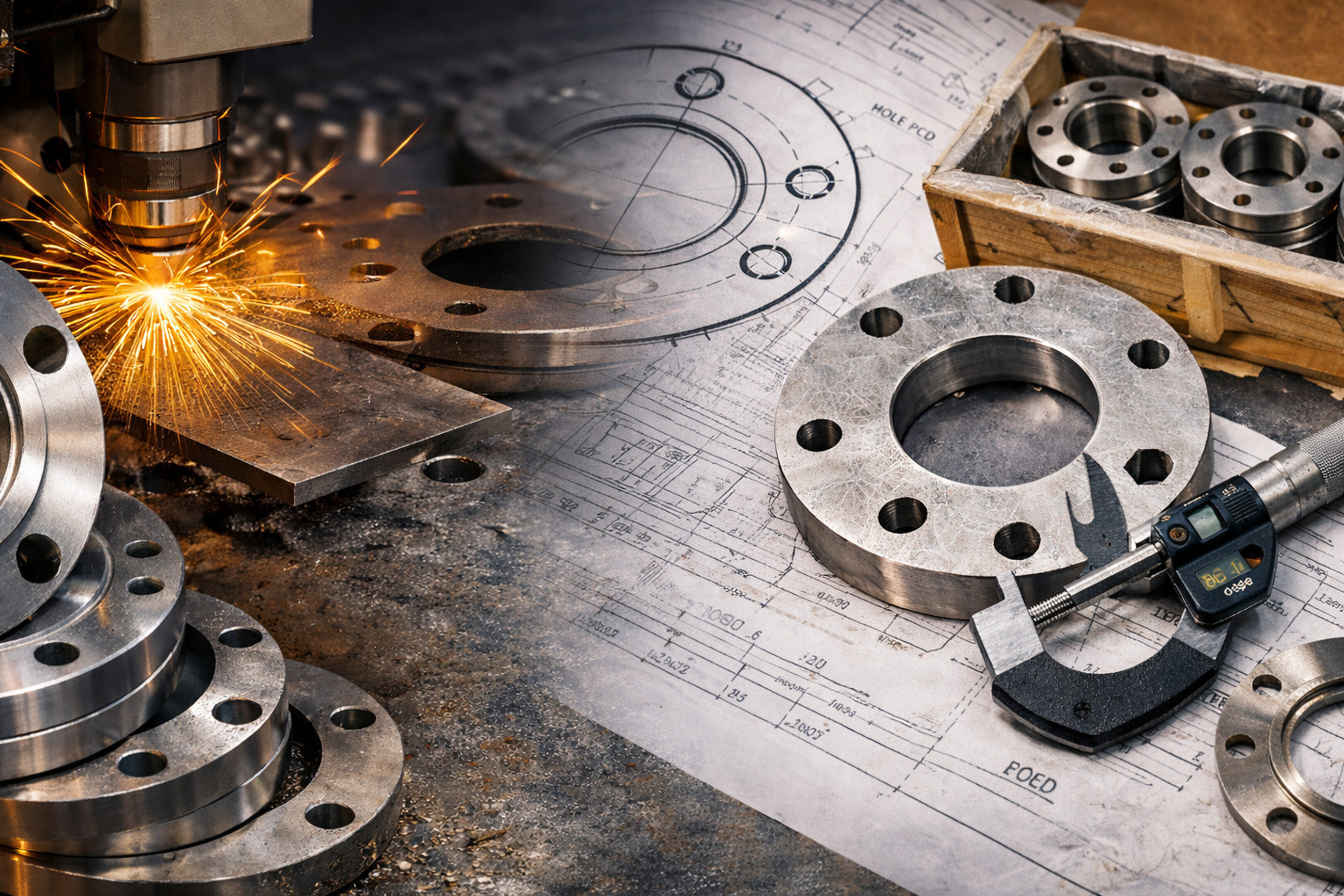

Custom Metal Flanges for Industrial & OEM Applications

Metal flanges play a critical role in industrial systems, enclosures, and OEM assemblies.

For procurement teams, sourcing flanges is less about price and more about

dimensional accuracy, material consistency, and repeatable quality.

Where Metal Flanges Are Commonly Used

- Industrial and electrical enclosures

- HVAC and ventilation systems

- Utilities and infrastructure equipment

- OEM machinery and fabricated assemblies

Materials Commonly Used for Metal Flanges

- Mild Steel (MS) – cost-effective for structural applications

- Galvanized Steel (GI) – corrosion resistance (120 / 275 GSM)

- Stainless Steel – SS304 / SS316 for outdoor or corrosive use

- Aluminum – lightweight OEM assemblies

Procurement Tip:

Always specify hole PCD, flatness tolerance, and surface finish in your RFQ.

Most flange failures originate from missing specifications, not manufacturing.

Why Buyers Choose Reliable Flange Manufacturers

- Consistent hole alignment and flatness

- Controlled burr removal and edge finish

- Clear material traceability

- Scalable production from samples to bulk

- Export-ready packaging

Custom Metal Flanges from Eterna

At Eterna Global Solutions LLP, we manufacture custom metal flanges as per

customer drawings and specifications, supporting both domestic and international buyers.

Our focus is on process discipline, repeatability, and long-term supplier reliability.

Request a Quote

Share your drawings, quantities, and material requirements.

Our team will review feasibility and respond with a clear quotation.

Contact Us