Lithium-Ion Battery Boxes & Enclosures: What OEMs Must Know Before Selecting a Manufacturer

Lithium-ion battery systems are central to electric vehicles, battery energy storage systems (BESS), telecom backup power, and industrial UPS applications. While battery chemistry receives most attention, the battery enclosure plays a decisive role in safety, durability, and long-term system performance.

For OEMs and system integrators, selecting the right lithium-ion battery box manufacturer directly impacts thermal behavior, ingress protection, corrosion life, and export compliance.

What Is a Lithium-Ion Battery Box?

A lithium-ion battery box (also called a battery enclosure or battery cabinet) is a fabricated housing designed to safely contain battery modules, BMS electronics, wiring, and thermal components.

- Electric vehicle battery packs

- Battery energy storage systems (ESS / BESS)

- Telecom backup battery systems

- Solar + storage installations

- Industrial and data-center UPS systems

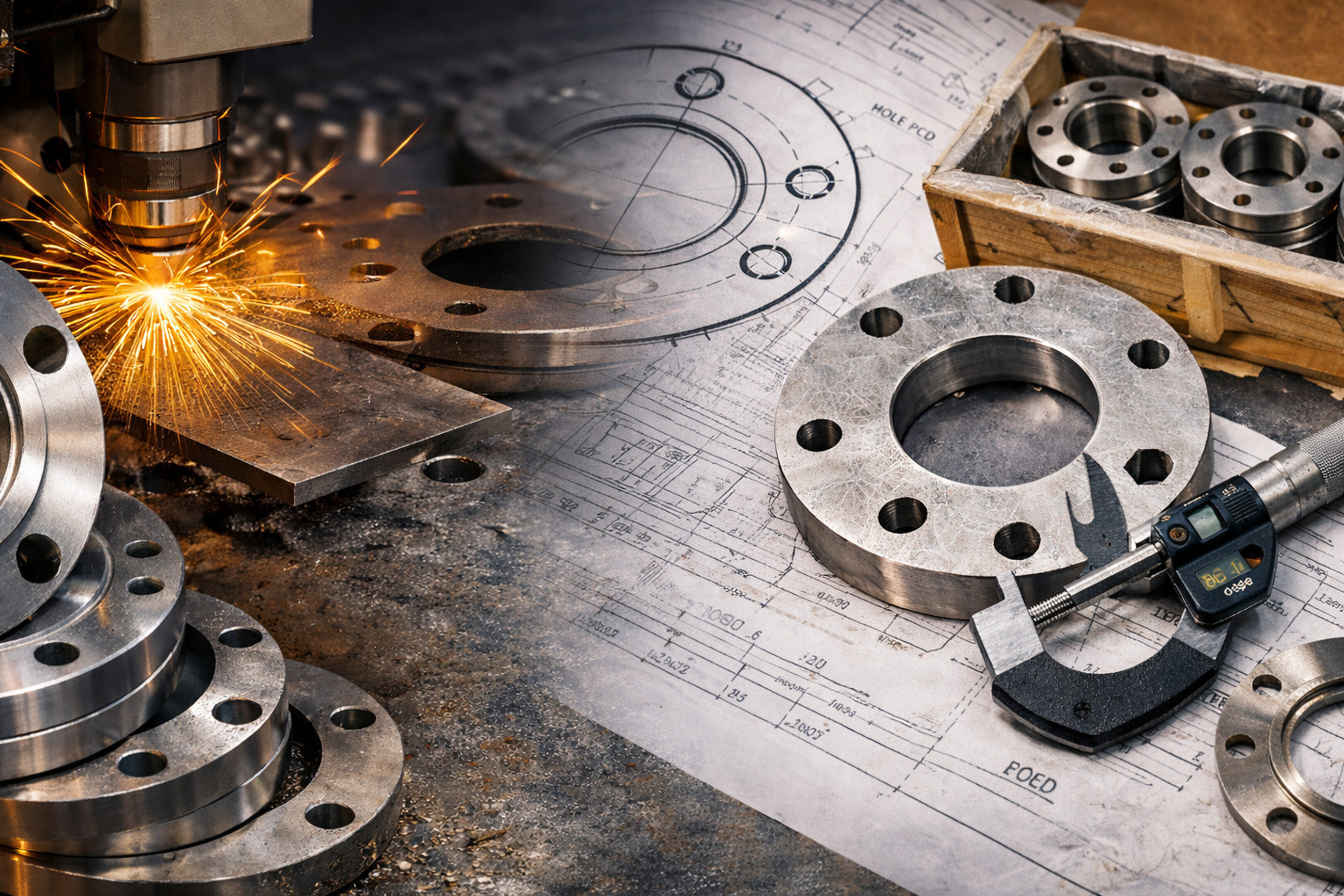

Key Design Requirements for Battery Enclosures

1. Material Selection

- Galvanised steel (120–275 GSM) – corrosion resistance with cost efficiency

- CRCA steel – indoor or controlled environments

- Aluminium – lightweight and thermally efficient

- Stainless steel – coastal or chemically aggressive locations

2. Thermal & Ventilation Design

Battery heat must be managed through enclosure layout and airflow strategy. Poor thermal design reduces battery life and increases safety risk.

- Passive ventilation or louvers (when permitted)

- Provision for fans or HVAC integration

- Clearance for heat dissipation and service access

- Space for insulation or fire-rated barriers

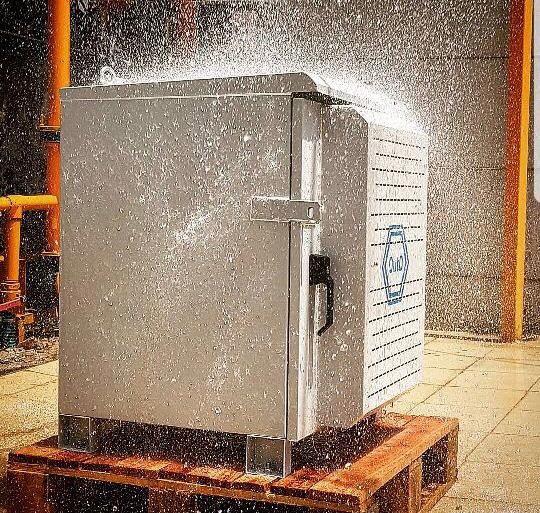

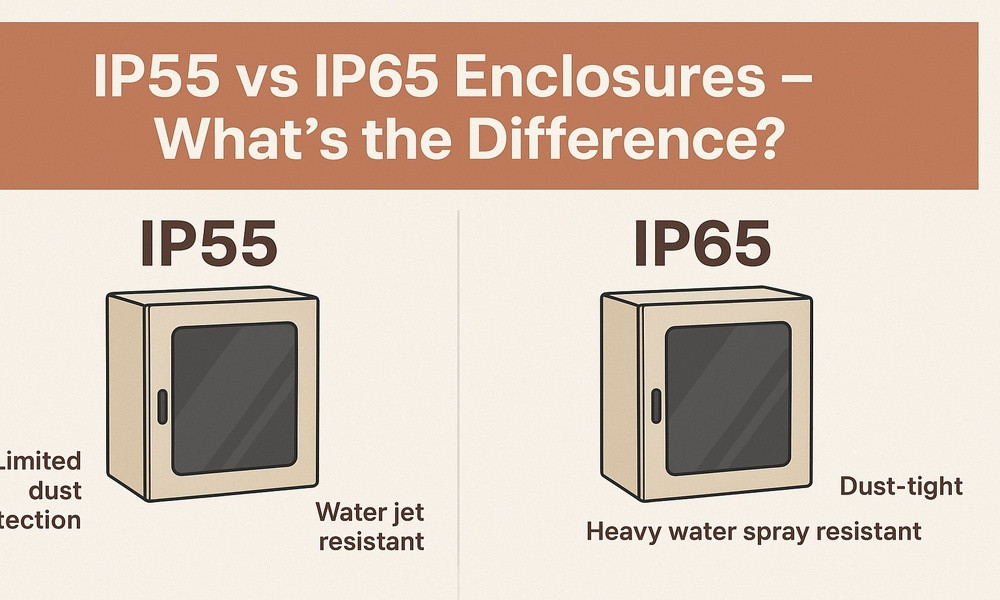

3. IP & Environmental Protection

- IP54 / IP55 / IP65 depending on exposure

- EPDM or silicone gasket sealing

- Rain sheds, drip edges, and sealed fasteners

4. Structural Strength & Safety

- Load-bearing design for battery modules

- Grounding points and controlled cable routing

- Resistance to vibration and transport stress

- Export-grade packaging compatibility

Why OEMs Prefer Specialized Battery Enclosure Manufacturers

- Faster prototyping and sampling

- Design-for-manufacturing (DFM) support

- Scalable production volumes

- Better consistency for export markets

Request a Quote or Technical Discussion

If you are sourcing custom lithium-ion battery boxes or enclosures for EV, energy storage, or industrial systems, we support prototype through production-scale manufacturing.

Contact Sales Send RFQFor faster quoting, share drawings, quantities, target IP rating, material preference, and destination country.

FAQ

Can lithium-ion battery boxes be customized?

Yes. Battery enclosures are typically customized based on battery size, thermal load, mounting, and application environment.

Which IP rating is suitable for outdoor battery enclosures?

IP55 or IP65 is commonly used for outdoor and industrial installations.

Do battery enclosures affect safety approvals?

Yes. Enclosure design impacts thermal behavior, grounding, and mechanical protection.

Are these enclosures suitable for export?

Yes, when manufactured with controlled processes and export-grade packaging.

-20082508144130.jpg)

-20082508385589.jpg)

-29112509574730.jpg)

-18122502213226.png)